Measuring Accuracy

Measuring accuracy - straightness and roundness under control

The STAINLESS Group has a 40 m2 expert laboratory equipped with machinery for carrying out metallurgical analyses. It includes almost twenty pieces of equipment such as an OES spectrometer, polishing machines, hardness testing machines, a laser micrometer, a drying oven, a tube furnace and an optical microscope.

With almost 100 years of experience and close cooperation with the main material manufacturers, we offer both standard and customized training courses to our current and future customers. These trainings are conducted by our technical manager and doctor of metallurgy, Thierry Turpin.

These training courses are adapted to the specific needs of the industry and are aimed at different target groups, be they laymen, purchasers, design offices or R&D departments.

State-of-the-art technology for flawless results

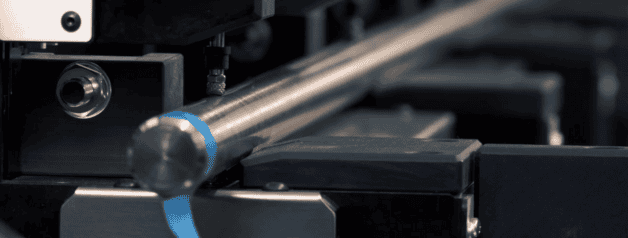

Our measuring system is based on a radially rotating scanning method that allows us to analyze our rods precisely:

Straightness check: We measure the straightness of bars with a diameter of 3 to 30 mm and a length of up to 4.5 meters with a maximum tolerance of 0.1 mm per meter.

Roundness analysis: Our machine detects shape deviations with an accuracy of 1 µm and thus guarantees an optimum level of quality.

Measurement logging: Every test is logged precisely, giving our customers full transparency about the properties of their materials.

A quality guarantee for our customers.

Thanks to this advanced measuring technology, we can guarantee our customers that the raw material they use meets their requirements and the highest quality standards. Every tested bar meets the specified tolerances, guaranteeing reliable and efficient production.

Optimizing your production processes

Perfectly straight bars are not only a sign of quality, they also play an important role in optimizing your production processes. Indeed they do:

They protect your machine tools by reducing vibrations and mechanical stress during turning.

They extend the service life of your tools and thus reduce maintenance and replacement costs.

You improve machining accuracy and ensure that parts meet specifications from the very first operation.

Our Additional Services

Let’s Build the Future Together

Interested in becoming our global partner?

We look forward to growing with you in your local market.